While lithium batteries have permeated the consumer market over the last two decades, adoption in the industrial stand-alone low-voltage (12V-48V) power market has been considerably slower. We'll cover some reasons below, but let's start with the most important question first: why would you want to use lithium for your industrial energy storage needs?

Here are what we consider the top 5 pros of lithium over other traditional battery types:

Lifespan – LFP batteries depending on group size and make/model have cycle life measuring into the thousands at 100% depth of discharge, which only improves at 80% and 50%- considerably more than even the highest quality Gel and AGM batteries.

Weight – Lithium batteries are constructed with materials weighing in far less than their Lead battery counterparts of similar group size. This is only a positive thing when it comes to shipping, handling, and installation. SunWize is particularly aware of how much of a challenge this can be, as our clients have plenty of sites where the only access is by hiking to the site. Why pack in a 55 pound AGM when packing in a 23 pound LFP is an option?

Energy Density – LFP batteries allow for more Amp-Hours in the same amount of space. The UPG12120 and LFP12180 batteries use the same housing, however the LFP battery is 33% higher capacity.

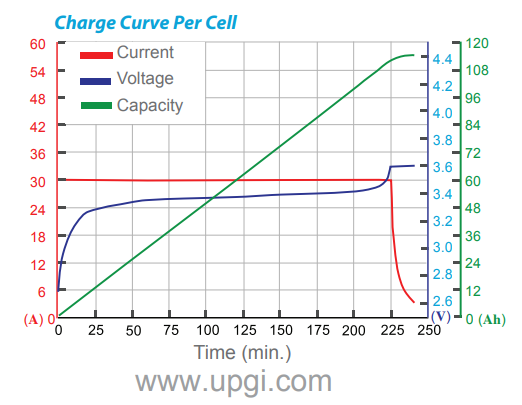

Greater Charge rates – LFP batteries allow for higher safe charge and discharge rates. A fairly common feature to see on many LFP batteries is C1 and 1/C rates allowed which is not common on most standard sealed lead-acid batteries.

Compatibility – Compatibility. LFP batteries are able to be used as drop-in replacements for VRLA applications with most charge controllers.

Now, let's look at some of the reasons for the slow adoption rate in the solar power industry. When using lithium batteries in solar power systems, there are a few points that must be considered to ensure proper system functionality:

- Charge controller programming (charging strategy, voltage setpoints, cold temperature foldback)

- Verified and/or stated compatibility with series/parallel stringing

- Manufacturer stated charging limitations

- System location

- BMS Reconnect

When Charging Lead Acid batteries there are typically 3-Stages, Bulk, Absorption, and Float. Generally speaking, most LFP batteries are compatible with 3-Stage charging systems, however most manufacturers recommend removing the Float stage, and switching to a 2-Stage charging algorithm. There are a number of ways to accomplish this, depending on what charge controller model is being used, and it is the responsibility of the system designer to ensure that all parts are compatible. In addition to the charging algorithm, proper voltage set points should be used to ensure that there are no under/over charging problems, and that temperature compensation is disabled, as with certain charge controller and battery combinations, over voltage events are possible, which can lead to the internal Battery Management System disconnecting the system from the LFP cells until the voltage falls to within safe limits. Morningstar's Energy Storage Partner (ESP) program is an ongoing collaboration with selected vendors, as a team effort to have comprehensive documentation on compatibility and recommended programming settings.

Each LFP product line will have different limitations with series and parallel connections. Some models, batteries are compatible with series stringing up to 48V nominal, or 2 parallel strings, but not both at the same time. Others will allow 4 Series and 4 Parallel strings simultaneously. Others will allow much wider parallel stringing- as many as 10 to 20. This aspect has a lot to do with the internal BMS built-in to the battery, its capabilities, and long term testing that the manufacturer has done.

Some Examples of Vendors SWPB Carries:

- UPG: Up to 48VDC Nominal, or 12VDC with two parallel strings

- RELiON: Up to 12VDC Nominal and four parallel strings.

- Rolls R-Series: Up to 48VDC Nominal and four parallel strings.

This is the area where system designers must get over the biggest hurdle: Temperature Limitations. LFP batteries in general do not recommend or prohibit charging of the battery below freezing temperatures. Some manufacturers list this limitation as a hard stop, others list it as optional, or strongly recommend against it.

Some LFP batteries have a built-in heater, which will consume either current coming in from the charging source to raise the internal battery temperature above freezing, other batteries have a built-in heater that will have a programmed duty-cycle and will use the battery cells to power the heater periodically to keep the battery above freezing. In both cases, the heater is a load that must be sized for during the system design phase.

With temperature considerations, some charge controllers have a parameter set called "Low Temperature Foldback", or something similar. These parameters allow charging current to be regulated relative to battery temperature. This is required for some lithium batteries, and is something that MorningStar provides control for with their ProStar PWM and ProStar MPPT solar charge controllers- and for specific setpoints recommendations, through the MorningStar ESP Program- there is comprehensive documentaion available for guidance.

If the information in this article strikes your interest, consider contacting a SunWize sales executive to discuss how lithium batteries could fit into your next project. Click here to browse and shop LFP batteries.