The Problem

A major utility company from Southern California contacted us because they needed to install some sensitive monitoring equipment on power poles. The power lines they needed to install this equipment on is carrying 12,000VAC power, however, their device requires 12VDC. Part of the difficulty for them is they couldn’t simply use a regular transformer to get that 12VDC because the EMI emissions would mask the signals they are trying to collect. An industry-standard method of getting around this problem is to use a special “Quiet” Transformer that could get them the power they need without interfering with the equipment they are putting up. However, due to long lead times, cost, and supply chain uncertainty, they decided to investigate alternative options utilizing solar.

The Solution

Total Systems For First Phase - 70

Array Size - 130W

Battery Capacity - 108AH

System Voltage - 12VDC

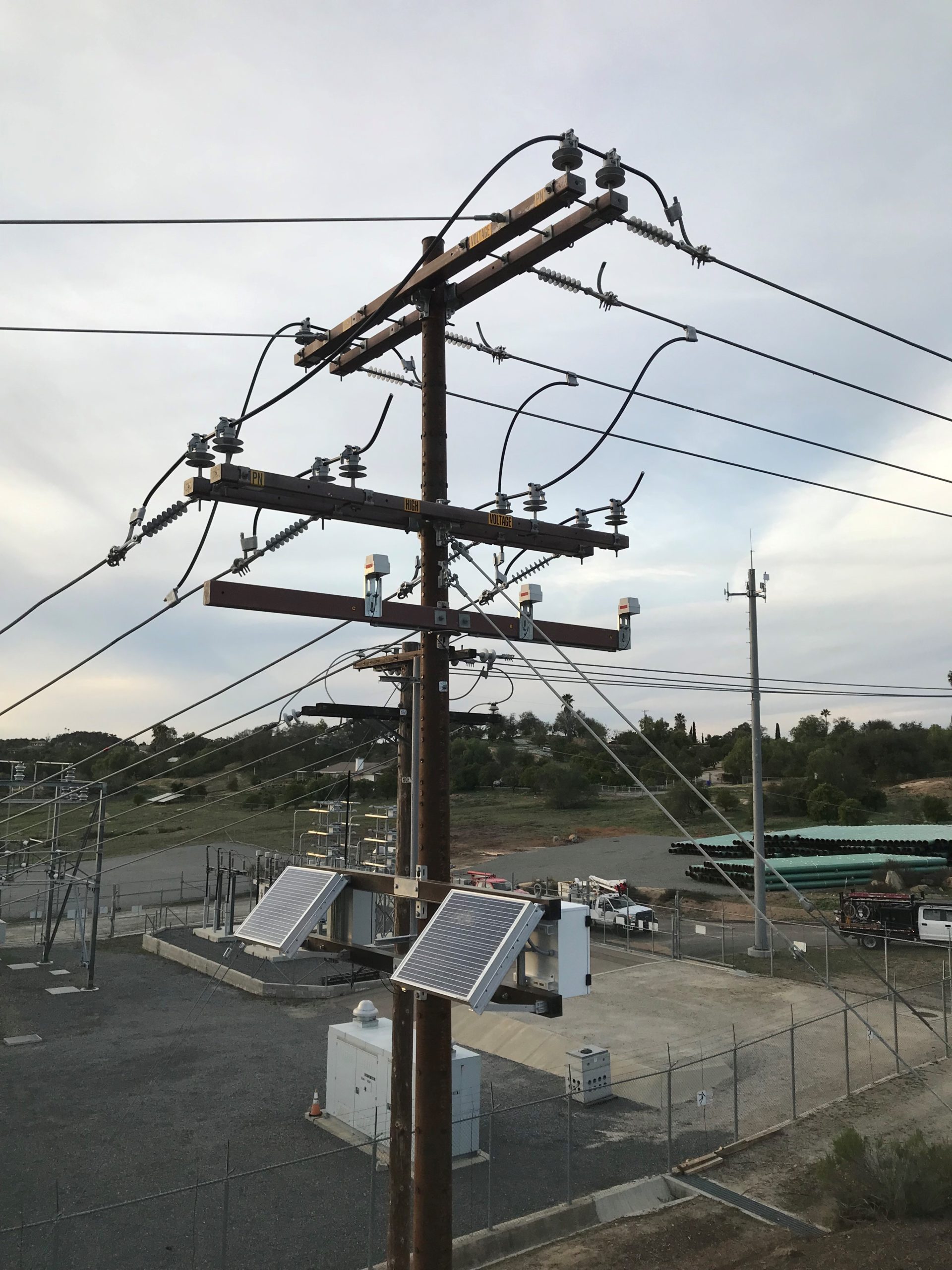

After getting the information we needed about the location these systems would be placed, and the information about how much power the devices require, we were able to design a simple and cost-effective 12V solar system, utilizing a MK Deka Gel Battery and a Morningstar SunSaver Charge Controller, that could be mounted to the power pole alongside the enclosure for their monitoring device. This was great for our customer because it removed a lot of complex and potentially dangerous parts from the installation prosses. According to our customer, “Solar also allows me to install the sensor without touching the primary (12,000 volt) wires and adding equipment that might cause a huge wildfire. Adding 12,000 volt components (small power transformer, fuse, fuse cutout, lightning arrestor, jumpers) adds to our risk very slightly but the solar at 12v is pretty much fireproof.”

For mounting the system to the power pole, we provided our 1 module side of pole mounts for the two 65-watt solar panels and the mounting bracket for our F1 enclosure. They then fitted them to a custom two crossarm mounting solution. That allowed the whole assembly to be easily tested and mounted. According to our customer, “Normally we use a 2” or 3” steel pole mounted to the cross arms with your pole brackets to allow the solar to face south. With the two cross arms, we could make an assembly that could be constructed and tested by our electrical contractor. The spacing of the arms puts the panels at the correct angle. All the crew has to do is mount it faced south and put in the battery. And close the breakers. Simple.”

In the end, the difference-maker for this customer was the fact that we used easy-to-get parts that we keep in stock, and they know they can count on us to deliver what they need when they need it. “The vendor for the sensor offers a solar package but it is imported so spare parts might be difficult to obtain. I used your parts because they are off-the-shelf stocked parts so I will definitely have spares and the parts are proven to work. You are a proven supplier.”

Want to Learn more?

This is just one example of the type of projects that work on. If you would like to learn more about the different types of custom systems that we design and build, click the link!

Lets Get Started!

Use this form to tell us about your system requirements, and your loads, and we will send you a quote!